Tooth

At R.L. Jain, we plan and stock a scope of extreme ground engaging tools for the right connections and the right gear and application. With high designing guidelines, our GET items are designed for the right fitment, wear and life span, and that implies decreased vacation and expanded usefulness for your work. They’re likewise designed for a straightforward establishment so you can continue ahead with your work.

Our ceaseless R&D separates us as experts in planning and creating extreme, heat-treated high-strength and wear-safe GET at market serious rates.

We stock the total scope of warmth treated teeth deployable for various machines and permitting administrators to meet all work capacities. We offer teeth for excavators, compactors, dozers, graders, scrubbers and loaders:

We stock heavy-duty, rock chisel, high penetration, tiger and standard teeth. All supplied teeth are high-strength, heat-treated, strong and wear-safe.

Our assortment of teeth utilizes the excavator’s force, and container burrowing execution, expanding execution and proficiency and fuel utilization.

Related products

Adaptor

R.L. Jain is the main supplier of wear parts items like adaptors. We spend significant time in items for excavators, loaders, tractors and penetrating apparatus. Our ground engaging tools are notable for their quality and superior in the most demanding jobs.

R.L. Jain addresses quite possibly the most innovatively progressed and presumed processing plants abroad to help the Indian business of G.E.T and Wear parts.

The adaptors are delivered utilizing top-notch crude material, well-informed organizations (Physical and synthetic), Scientifically planned with exactness, reasonable fitment, Strong protection from wear, high strength, high effect and long-life execution.

Register Now To PurchaseScarifier

| Material Grade | SS304/316L |

| Material | Stainless Steel |

| Surface Treatment | Polished |

| Finish | Glossy |

| Shape | Cylindrical |

| Application | Industrial |

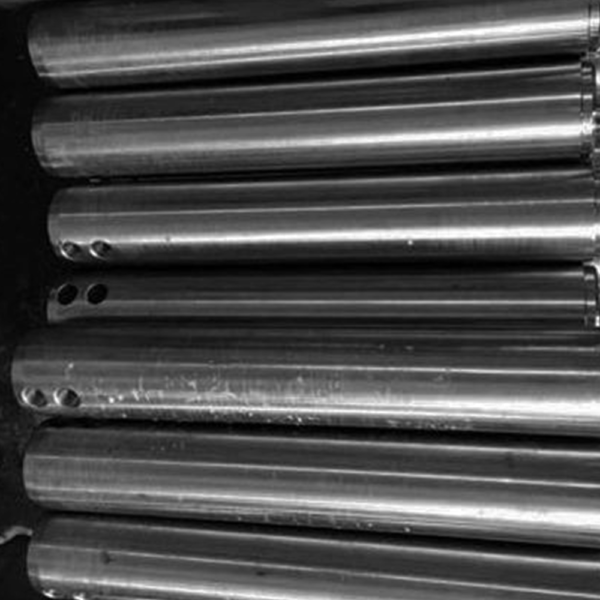

Pin

Mounting Pin

| Material Grade | SS304/316L |

| Material | Stainless Steel |

| Surface Treatment | Polished |

| Finish | Glossy |

| Shape | Cylindrical |

| Application | Industrial |

Grader Blade

Side Cutter

We offer a wide selection of edge and side cutters fabricated from a few evaluations of high carbon and boron steel. A significant number of these items are produced using both high carbon and boron steel, which are heat-treated and utilized for earthmoving and hardened to improve life while meeting requesting mining applications.

What is the side cutter for the excavator?

The principal work is the grader device and other helper gear, which supplement each other for soil reaping, scratching, evening out conveyance activity, upkeep and support of rock street, roadbed, dirt or turfing, digging, scratching. Incline, evening out. The brace can help forestall sharp edge and side shaper harm.

Benefits/Features of Side Cutter

- Through proficient extinguishing hardening cycles to ensure great mechanical properties, high strength and better wear obstruction than bowing and breaking.

- Hardness 280-320HB for low wear and long life, expanding the worth of your items to your business by augmenting the sturdiness of your items.

Our Advantages

- World-Class Quality

- Sell Directly With Reasonable Price

- Experience In supply Excavator And Bulldozer Spare Parts

- Professional Sales Team, Quality Inspection.